WILA LASER Main Processing Line Equipments Display:

Line 1:

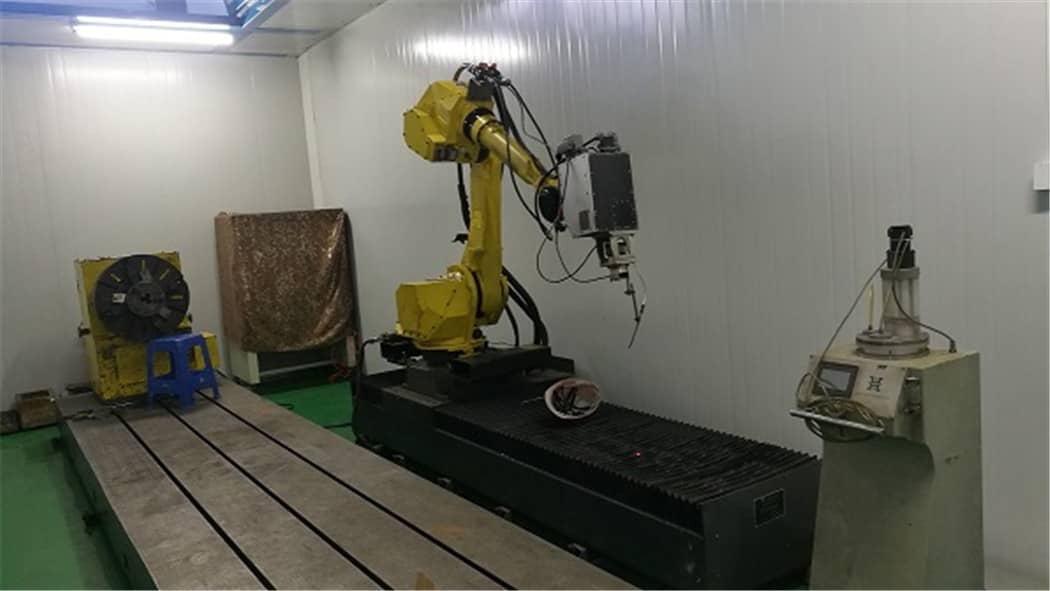

Production line 1 adopts internationally advanced direct semiconductor lasers, equipped with advanced robots and machine tools, to achieve eight-axis combined transportation control. It adopts the original imported DILAS (power 3KW) semiconductor laser system imported from Germany, with a high power conversion rate, stable light output, and intelligent fault diagnosis system. The laser spot can be adjusted uniformly within 3*3mm to 3*19mm, which can meet the requirements of precise laser quenching and alloying. Chemical and cladding requirements. Choose Japanese FANUC M710ic/50 robot equipped with semiconductor laser head, equipped with communication interface, digital/analog signal interface, convenient for dialogue and control of the system, realize the six-axis flexible movement of the laser head, supplemented by two-axis motion machine tool, based on AC servo motor drive, To achieve eight-axis combined transportation, to meet the laser surface manufacturing and remanufacturing of complex shape parts. Use Siemens S7-1200PLC as the main control unit to realize the one-key operation of DILAS laser, FANUC robot, HGSF-1A powder feeder, and man-machine interface.

Metal laser surface quenching, alloying, and cladding can be performed according to customer requirements to realize laser surface manufacturing or remanufacturing of products.

Line 2:

Production line 2 uses the German LASER LINE original LDF4000-400 (power 4KW) fiber-coupled semiconductor laser system, the power conversion rate is as high as 45%, and the trouble-free operation rate is as high as 99%. The time-sharing two-way electronic shutter is connected to the laser quenching processing head, laser cladding processing head, and welding processing head through two optical fibers with core diameters of 600 μm and 400 μm. Select KUKA KR60HA robot, equipped with laser working head for laser processing of workpieces, equipped with communication interface, digital/analog signal interface to facilitate communication with the laser control system and deep integration, and can be connected to DCAM software, control IRC5 upgrade can achieve two-dimensional transformation It realizes six-axis linkage function and is equipped with advanced robots and machine tools to realize eight-axis linkage control. Siemens S7-1200PLC is used as the main control unit to realize the one-key operation of the LASER LINE laser, KUKA robot, HGSF-1B powder feeder, and man-machine interface.

WILA's production line has the functions of laser quenching, laser alloying, and laser cladding, which can realize advanced manufacturing and remanufacture of laser surfaces and 3D laser printing of parts.

Line 3:

This set of equipment is independently integrated by WILA, adopts the international advanced level of semiconductor-coupled fiber output laser, and is equipped with advanced robots to realize 7-axis linkage control. Using German LASER LINE original LDM3000-600 (power 3KW) fiber-coupled semiconductor laser system, the power conversion rate is as high as 45%, and the trouble-free operation rate is as high as 99%. It is connected to the OTZ-5 variable spot laser quenching processing head through an optical fiber with a core diameter of 600μm. The processing head can realize the step-less adjustment of different sizes of spots, and the adjustment range is 3*5mm~3*79mm, which is very satisfying. Laser quenching and cladding processing of various products.

Select KUKA KR60HA robot, equipped with laser working head for laser processing of workpieces, equipped with communication interface, digital/analog signal interface to facilitate communication with the laser control system and deep integration, and can be connected to DCAM software, control IRC5 upgrade can achieve two-dimensional transformation It can realize six-axis linkage function. Siemens S7-1200PLC is used as the main control unit to realize the one-key operation of the LASER LINE laser, KUKA robot, HGSF-1B powder feeder, and man-machine interface.

Line 4:

The No. 4 production line is independently integrated by WILA, adopts nationally produced equipment, and uses low-power and low-load equipment for the small product market, reducing equipment costs. Using domestic Raycus RFL-A2000D (power 2kw) fiber output semiconductor laser, it has the characteristics of high reliability, maintenance-free, high photoelectric conversion efficiency, convenient control interface, and fast modulation capability. It can be applied to laser welding, cladding, and quenching. In other fields, the light is transported from the fiber with a core diameter of 600μm to the integrating copper mirror, and the copper mirror can be replaced to output light spots of different sizes to meet the laser quenching of various products. The robot adopts the domestic Daye small robot with a load of 8kg and a special lightweight laser processing head. It is equipped with a communication interface and a digital/analog signal interface to facilitate communication with the laser control system and deep integration, which can realize the seven-axis linkage function. Siemens S7-1200 PLC is used as the main control unit to realize the one-key operation of the laser, robot, powder feeder, and man-machine interface. And integrate all the equipment in the operation cabinet to realize the processing station system. The production line can realize the processing of laser quenching and laser cladding of batches of small products.