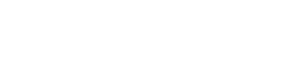

In response to the diversified processing needs of enterprises, laser processing systems usually need to be customized, taking into account product functionality and input costs. Based on years of hardware design experience, WILA Laser adopts modular design concepts to formulate the best equipment manufacturing plan, provides a reasonable combination and upgrade space for core components, motion mechanisms, quality monitoring, application software, etc., and provides verification of supporting laser processing technology service. Including the development of small, super large, single function, and multi-functional compound equipment.

• Laser processing head: optical head, nozzle, etc.

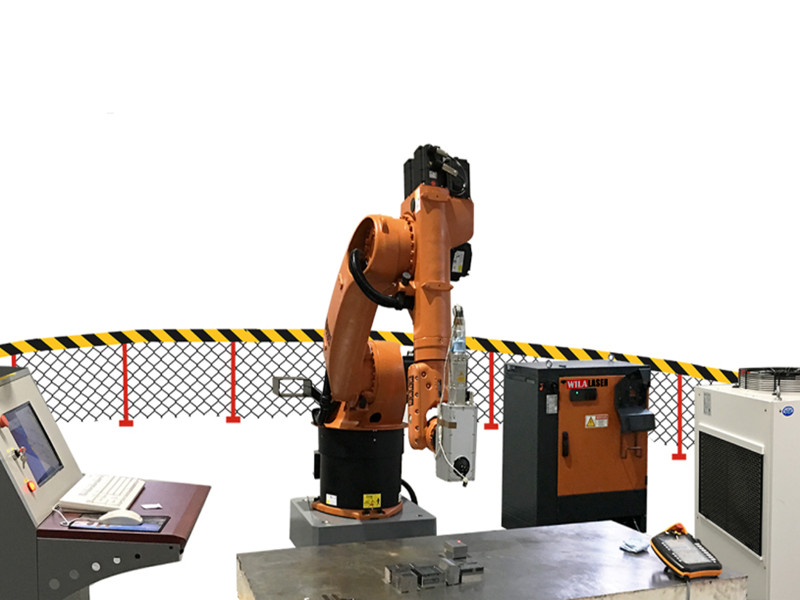

• Motion mechanism: CNC machine tools, 6-axis robots, positioners, gantry structures, etc.

• Online monitoring: online monitoring and data analysis of images, temperature, floor height, etc.

• Software: automatic layering software, adaptive repair software

• Environmental system: vacuum environment, argon-filled environment

• Remote monitoring and diagnosis

Commissioned Processing:

WILA Laser is equipped with high-performance equipment in both China and India. Our experienced process engineers can not only provide customers with mass laser processing services for products in the company, but also provide customers with on-site production line production and processing services, providing materials, Technical support for the entire production chain, such as processing, performance evaluation, and connection of front and back procedures, does not require customers to invest in high equipment or hire professionals.

• Ultra-high-speed laser cladding

• Inner wall laser cladding

• Laser repair & additive manufacturing

• Laser welding

• Laser hardening

• Laser micromachining

R & D Management:

Tailor-made research and development solutions for customers, give full play to the unique advantages of laser processing in your field

• Analyze the feasibility of applying laser processing to existing products

• Evaluate R&D resources, including R&D team building and hardware requirements

• Set milestones for R&D achievements and industrial transformation cycle

• Establish a recyclable technology learning and upgrade mechanism for enterprises to achieve sustainable development

Professional Training:

WILA Laser provides open technical training services in both China and India. Technical professionals and senior engineers in China and India provide customers with one-stop personalized guidance, including training in the process, equipment operation and maintenance, and software application. According to customer needs, you can choose China or India as the training location, and arrange targeted technical inspections and exchanges in Germany or the United States for customers. Partners include Aachen Additive Manufacturing Center (ACAM) in Germany and ATLAS in the United States.

• Basic theory and technology of laser processing

• Process development and production technology

• System operation and maintenance technology

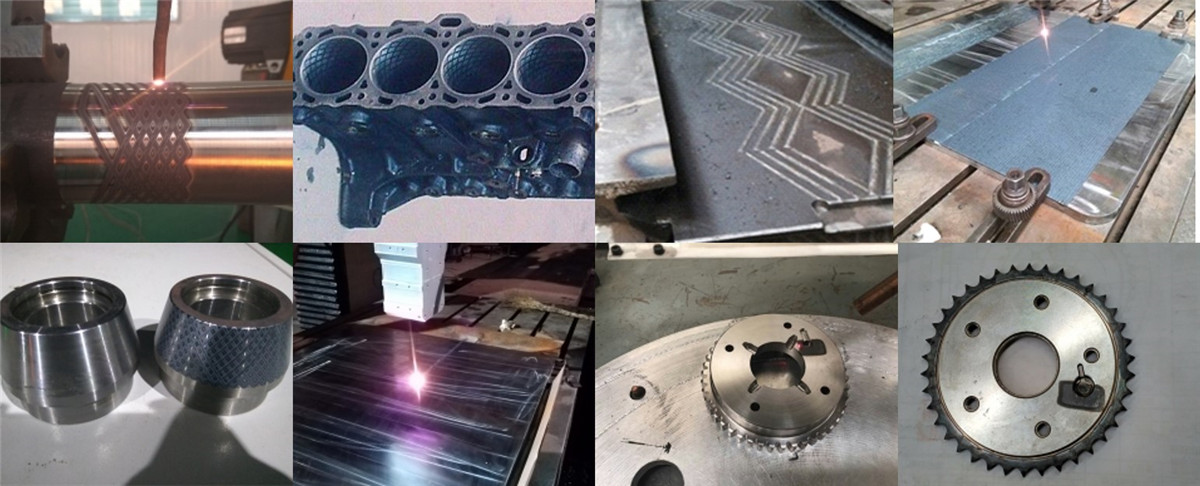

Our Main Professional Business:

1. Laser surface heat treatment:

Laser surface hardening is a new type of surface hardening process with high efficiency and strong operability. Traditional surface heat treatment processes such as high-frequency quenching, carburizing treatment, nitriding treatment, etc., have the defects of uncontrollable quenching area, long heat treatment time, thin quenching depth, and local hardening. Laser surface hardening can not only realize the controllable hardening area and high hardness, but also the hardening depth is deeper than the traditional process, and the efficiency is higher.

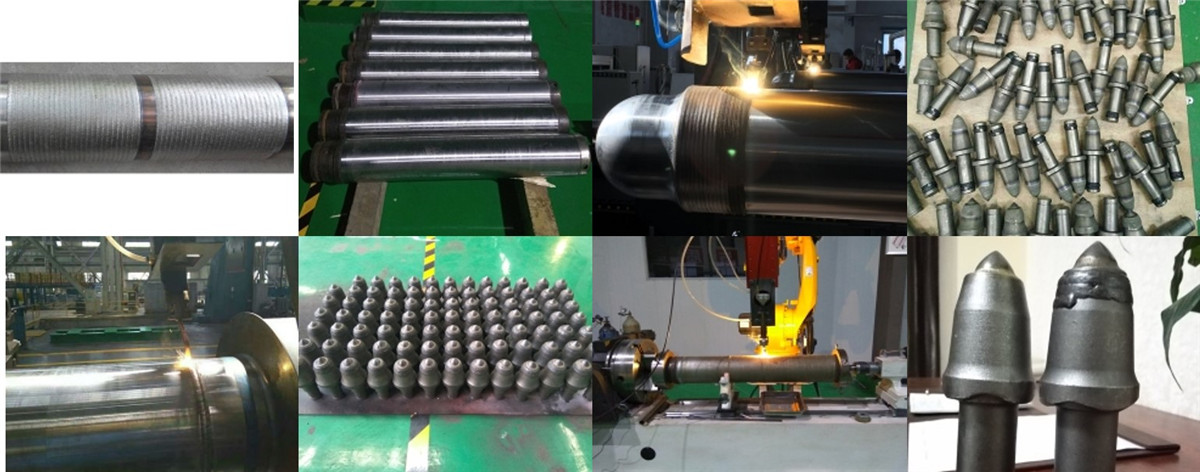

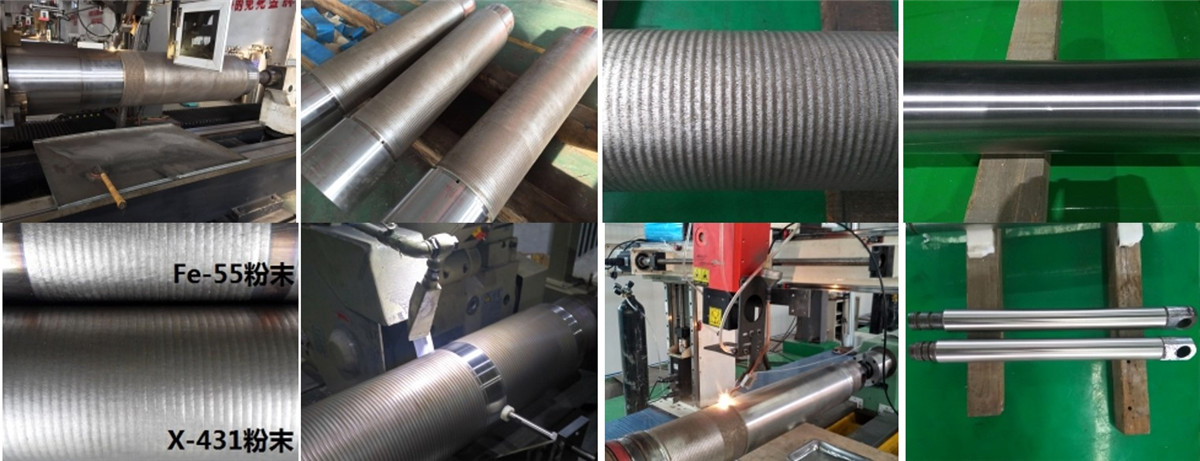

2. Laser cladding:

Process characteristics: 1) The laser cladding layer and the substrate are metallurgically combined (the dilution rate is less than 5%, and the porosity is 0); 2) The thickness of the cladding layer during laser cladding of the matrix material is 0.3-2.5mm; 3) Laser The temperature rise of the substrate during the cladding process does not exceed 180°C, and there is basically no thermal deformation after laser cladding; 4) Laser cladding technology can cladding ultra-high melting point materials; 5) The cladding layer and its interface have a dense structure and crystal grains Small, no pores, inclusions, cracks, and other defects; 6) The laser cladding layer can form a functionally gradient material, which improves the use performance and safety performance; 7) The laser cladding technology can realize the local precision processing of the workpiece; 8) Laser cladding After that, the surface hardness, strength, corrosion resistance and wear resistance can be improved.

3. Laser instead of electroplating:

In the coal, mining machinery, construction machinery, aviation, and other industries, some hydraulic cylinders use traditional electroplated hard chrome surface treatment to make the surface of the piston rod wear-resistant, temperature-resistant, and corrosion-resistant, causing great pollution to the environment. Causes great harm to the body of the operator and the local people in the electroplating plant. WILA Laser uses laser cladding technology to replace the traditional hard chromium electroplating process, which not only does no harm to the environment and personnel but the service life of the workpiece is also increased by more than 5 times compared with the electroplating process.

4. Domestic on-site repair case:

WILA Laser can provide you with comprehensive and high-quality integrated services for designing optimized solutions. WILA Laser's laser processing equipment uses high-power semiconductor lasers as the heating source. It has the characteristics of small size and easy transportation. It can provide enhanced and on-site maintenance programs for large parts under various special working conditions and adopts leading automated control systems, etc. Additional features. While designing optimized solutions for our partners, we also provide comprehensive and high-quality integrated services.

5. Inner hole melting copper:

The inner hole copper melting equipment and production process independently developed by WILA Laser technicians can realize the abrasion resistance, corrosion resistance, and remanufacturing enhancement of the inner wall of the cylinder block and pipeline workpieces such as the inner wall of the column bottom cylinder of the hydraulic support.