Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

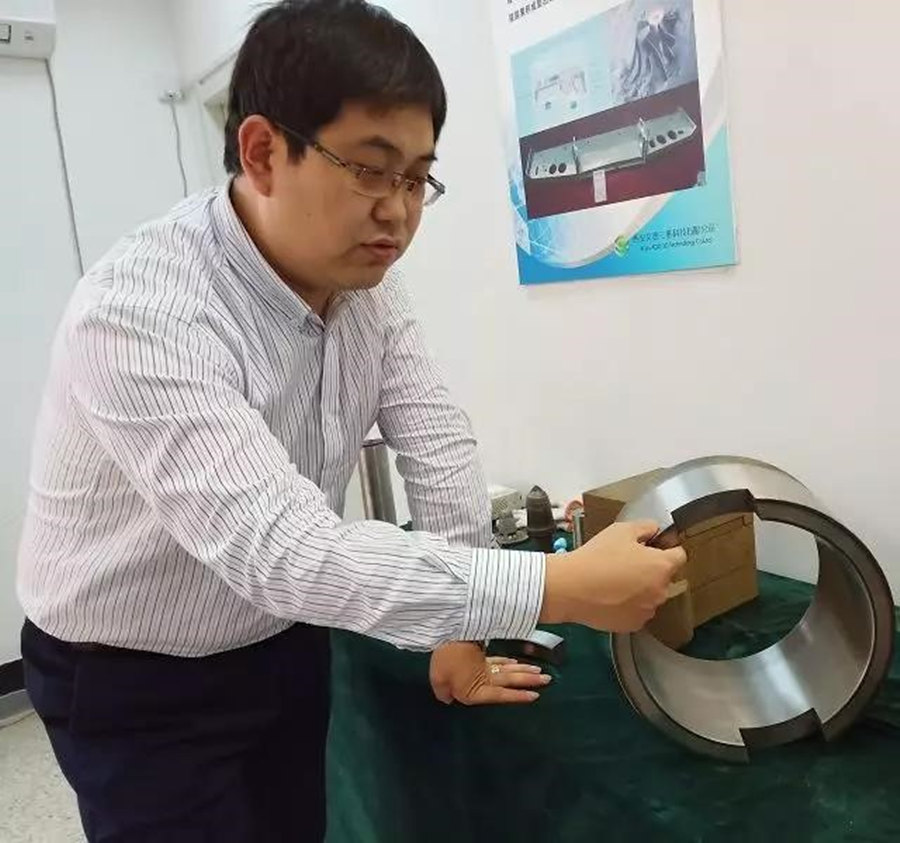

Laser cladding technology is mainly used in the surface treatment of large high-value parts, especially in the surface treatment of large iron-based rotating parts. At this stage, for the cladding of the outer surface of the part, the related technology has become mature. The laser cladding of the inner surface of the thin-walled part by WILA is a major breakthrough in this technology.

Payment:

TTProduct origin:

ChinaShipping port:

ShanghaiLead Time:

20 days after receiving the deposit

Inner wall laser cladding repair service

Product description:

The inner wall laser cladding technology replaces traditional electroplating, which is low cost, more environmentally friendly, and can be repaired repeatedly. In the past, customers needed to work in three companies to complete the repair of the outer wall of the piston rod, the inner wall of the cylinder, and the outer wall. WILA can be completed at the same time, which not only saves customers a lot of time, but also reduces shipping costs by nearly 25%, and the product after-sales problems are easy to deal with.

After 2 years of theoretical analysis and extensive experimental verification, WILA has finally developed a cladding equipment for the inner surface of parts such as 27SiMn, 40CrMnSi and other materials. The equipment uses IPG fiber-coupled lasers, and independently develops control systems, carrying and operating devices.

WILA used the laser cladding method to modify the surface of the inner wall of the cylinder and studied the programmable logic controller (PLC) to control the laser cladding coating process parameters on the cross-sectional morphology of the cladding layer, the formation of the cladding layer, and The influence of the dilution rate is compared, and the wear resistance of the quenched and tempered cylindrical substrate, the flat cladding layer and the cylindrical inner wall cladding layer are compared and analyzed.

The results show that the suitable laser cladding process parameters for the inner wall of the quenched and tempered 35CrMo hollow cylinder are laser power 1 400 W, scanning speed 6 mm/s, and powder feeding rate 12 g/min. At this time, the quality of the cladding layer is better; As the distance from the top of the surface layer increases, the hardness of the flat cladding layer and the inner wall cladding layer shows a gradual decrease, and the hardness of the flat cladding layer, the inner wall cladding layer and the corresponding heat-affected zone are all higher than the 35CrMo alloy matrix. The room temperature and 300°C high temperature wear resistance of the cladding layer obtained under the optimized laser cladding process is greatly improved compared to the cylindrical substrate, and the wear resistance of the inner wall cladding layer is equivalent to or slightly lower than that of the flat cladding layer. It can meet the requirements of high hardness and high wear resistance of the inner wall surface modification of cylindrical parts.

click here to leave a message