Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

Explosive spraying is a method in which oxygen and acetylene gas are mixed in a certain ratio in a specially designed combustion chamber and then detonated, so that the powder is heated and melted and the particles are hit at high speed to form a coating on the surface of the part.

Payment:

TTProduct origin:

ChinaShipping port:

ShanghaiLead Time:

20 days after receiving the deposit

Spray paint explosion service

Overview:

Explosive spraying is characterized by high particle flight speed and high kinetic energy, so explosive sprayed coatings have: First, the bonding strength of the coating and the substrate is high. Second, the coating is dense and the porosity is very low. Third, the roughness of the coating surface is low after processing. Fourth, the surface temperature of the workpiece is low. In explosive spraying, when the acetylene content is 45%, the oxygen-acetylene mixture can produce a free combustion temperature of 3140℃, but it may exceed 4200℃ under explosive conditions, so most powders can melt. The length of powder transported in the high-speed gun is much longer than that of the plasma gun, which is also the reason for the high particle velocity. Explosive spraying can spray metal, cermet and ceramic materials, but due to the high price of the equipment, high noise, and oxidizing atmosphere, it is not widely used.

principle:

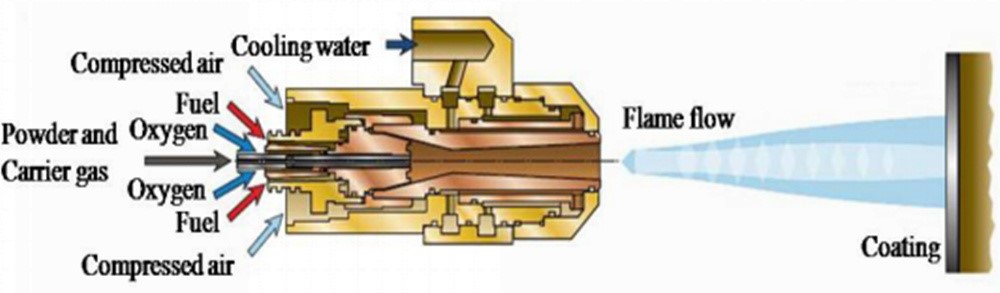

Explosive spraying is the use of gas explosion to generate high energy, heating and accelerating the spraying powder, so that the powder particles bombard the surface of the workpiece at a higher temperature and speed to form a coating. When spraying, a certain pressure and proportion of oxygen and acetylene are first introduced into the inner cavity of the water-cooled spray gun from the air inlet, and then the powder is fed in from the powder supply port. Then the spark plug is ignited, and the mixed gas of oxygen and acetylene burns and explodes, producing high temperature The high-speed airflow heats the powder and hits the surface of the substrate at a high speed (about 3 times the speed of sound) to form a coating. Nitrogen gas is introduced to clean the barrel to prepare for the next spraying. Repeat this.

Features:

The characteristic of explosive spraying is to heat and melt the sprayed material with the heat energy of the sudden explosion, and use the high pressure generated by the explosive shock wave to spray the sprayed powder material on the surface of the workpiece substrate at a high speed to form a coating. Its main advantages are as follows.

(1) The range of sprayable materials is wide, from low-melting aluminum alloy to high-melting ceramics, and the powder particle size is 10~120μm.

(2) The heat damage of the workpiece is small. Because explosive spraying is pulsed, the time for each heated airflow and particle impact is short, and the nitrogen cools the workpiece again. The temperature of the workpiece is lower than 200℃, so the substrate has little thermal damage and no deformation and phase change.

(3) The thickness of the coating is easy to control, the machining allowance is small, and the maintenance operation is convenient.

(4) The roughness of the explosive spray coating is low, which may be less than 1.60μm, and the roughness can reach 0.025μm after grinding.

(5) During the spraying process, carbide and carbide-based powder materials will not produce carbon decomposition and decarburization, so as to ensure the consistency of coating composition and powder composition.

(6) Low oxygen consumption and low operating cost.

click here to leave a message