Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

WILA focuses on the laser surface treatment of metal materials, using laser cladding, laser heat treatment, laser welding and other technologies to improve the physical and chemical properties of materials and equipment parts and extend their service life. The company can provide customers with laser additive manufacturing, metal material quenching enhancement, key parts wear repair, equipment remanufacturing services, etc.

Payment:

TTProduct origin:

ChinaShipping port:

ShanghaiLead Time:

20 days after receiving the deposit

Injection mould repair

Product description:

Injection molding molds are generally complex in shape, with edges, corners, thin walls, etc., where serious stress concentration will occur. Due to long-term use under high temperature, high pressure, and high stress conditions, when the stress concentration exceeds the strength limit of the material, microcracks will occur. With the continuous action of stress, the cracks continue to expand, and fracture failure will occur if they expand to a certain extent. Fracture failure is a more harmful form of rapid failure, which will directly lead to the scrapping of the mold.

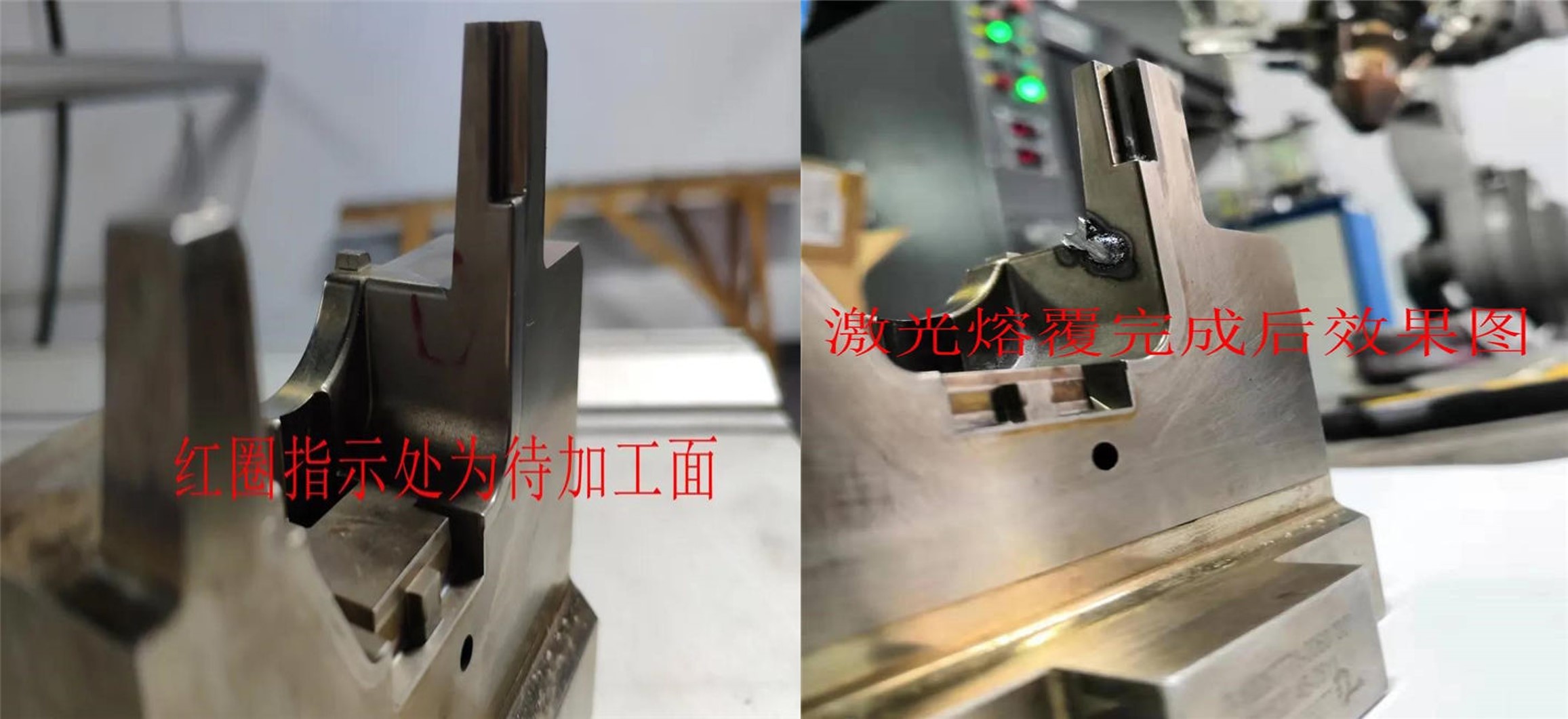

Laser cladding can accurately control the heat input, the workpiece heating and cooling speed is fast, the thermal distortion is small, and the cladding layer with dense structure and superior performance can be produced on the surface of the mold. After determining the laser cladding process parameters, it is superior to the traditional surfacing repair process and has high reliability.

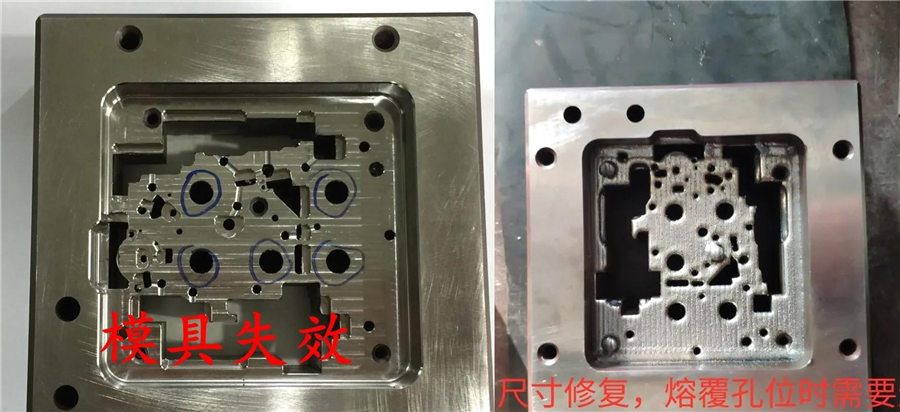

The surface of the injection mold is worn and corroded during use, and the surface roughness of the cavity becomes larger and the mold size is out of tolerance, which causes the quality of the plastic product to be unqualified, which leads to the failure of the mold. According to statistics, among all the failure modes of injection molds, the cavity surface wear and corrosion failure modes account for about 40 to 50%.

After the following mold is used to produce about 200,000 parts, the surface of the mold cavity is out of tolerance by 5-10 wires due to wear and corrosion, resulting in unqualified product quality.

The WILA Laser team applied laser cladding technology to repair the damaged surface of the injection mold cavity, and through subsequent processing, it reached the standard for reuse.

click here to leave a message