Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

In the process of modern coal mining, affected by the complex underground environment of the coal mine, the hydraulic support has been in a weak acid and high humidity state for a long time, causing serious damage to the hydraulic support's cylinder structure.

WILA uses a laser cladding process to repair the inner wall of the cylinder barrel, which has a very good effect on large over-tolerance range, large area corrosion, and cylinder expansion.

Payment:

TTProduct origin:

ChinaShipping port:

ShanghaiLead Time:

20 days after receiving the deposit

Inner hole laser cladding repair service

Technical features:

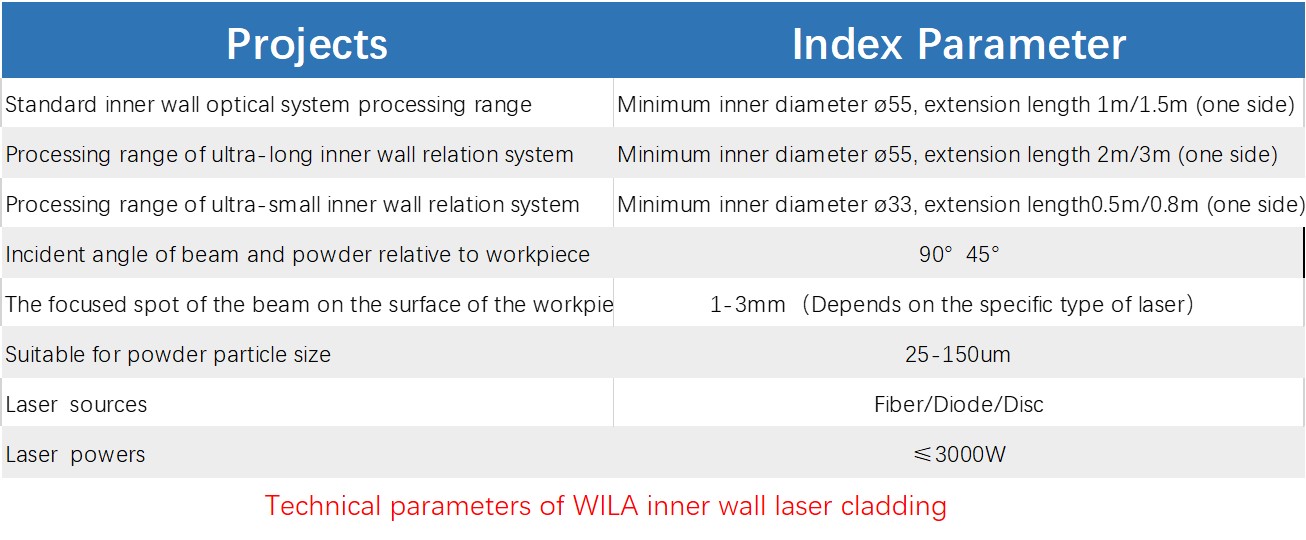

Highly adaptable solution for part inner wall processing

The application requirements for surface cladding and repairing of the inner walls of some high-load parts continue to increase, hoping to have excellent wear resistance, erosion resistance, and corrosion resistance, such as bearings, molds, cylinders, cylinders, extrusion cylinders, valves, etc. With the improvement of product service performance and structural complexity, the industry has put forward higher and higher application requirements for the applicable limit scale, versatility, and high quality and efficiency of inner wall laser cladding and repair technology.

Different from the outer wall laser cladding, the laser beam, powder, and cooling water in the inner wall laser cladding processing head need to be transmitted through a long distance in a limited space to reach the top of the optical head. In order to adapt to the processing of smaller and longer inner diameter parts, the inner wall laser The cladding processing head is required to have the characteristics of high integration, high precision, and high rigidity.

Technical advantages:

• High integration and high stability: powder circuit, air circuit, water circuit and light circuit are all integrated in the tube

• Applicable minimum pipe inner diameter: Ф33mm

• Maximum extension length: 3mm on one side

• Suitable for blind hole processing: powder flow, beam angle 45°incidence design

• Multi-function fast switching: changing the front nozzle can complete various processes such as cladding, additive, welding, quenching, etc.

• Applicable to a variety of materials: can prepare iron-based, nickel-based, cobalt-based, copper-based, composite materials and other alloy coatings

• Process online monitoring: real-time monitoring of the image and temperature of the processing area can be realized, and the laser in the tube can quickly locate and align

Technical Background:

The inner wall laser cladding optical system, also called ICO (Inner Cladding Optics), is the core component of the inner wall laser cladding system. WILA Laser’s inner wall laser processing system is designed with full consideration of the convenience of application. The system adopts modular design. Machine tools and robots have different motion forms, equipped with different specifications of inner wall optical systems, which can realize the integrated integration of inner and outer wall laser cladding. . At the same time, in accordance with different product characteristics and process requirements, supporting process specifications for different methods of inner wall laser cladding, repair and hardening have been developed.

Industry application:

1. Coal machinery:

It is used for the preparation of corrosion-resistant coatings on the inner wall surface of middle cylinder parts. It can replace the traditional arc copper melting process. It can also prepare stainless steel and copper alloy coatings on the inner wall surface according to application requirements to reduce costs or perform rapid repair of local damaged areas on the inner surface. repair.

2. Lifting machinery:

It is used for the preparation of wear-resistant hard coatings, erosion-resistant or corrosion-resistant coatings on the inner wall surface of oil cylinder parts, and the rapid repair of local defects on the inner surface.

3. Offshore Engineering Machinery

Used for the preparation of wear-resistant hard coatings, erosion-resistant or corrosion-resistant coatings on the inner surface of parts, rapid repair of local defects on the inner surface, and laser cladding repair of narrow and restricted locations.

4. Mould industry

It is used for the preparation of wear-resistant, high-temperature-resistant and erosion-resistant coatings on the inner surface of injection molds, as well as the rapid repair of local defects on the inner surface of the mold, as well as the laser cladding repair of narrow and restricted locations.

5. Oil drilling

Used for the preparation of wear-resistant hard coatings, erosion-resistant or corrosion-resistant coatings on the inner surface of bearing sleeves, oil drill collars and other parts, rapid repair of local defects on the inner surface, and laser cladding repair of narrow and restricted locations.

click here to leave a message