Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

The hydraulic column is an important part of the hydraulic support of coal mining equipment, which mainly includes the piston rod and the cylinder tube. Due to the very harsh working environment, the outer surface of the piston rod and the middle cylinder tube must require strict anti-corrosion performance.

Payment:

TTProduct origin:

ChinaShipping port:

ShanghaiLead Time:

20 days after receiving the deposit

Hydraulic support piston rod repair

Products description:

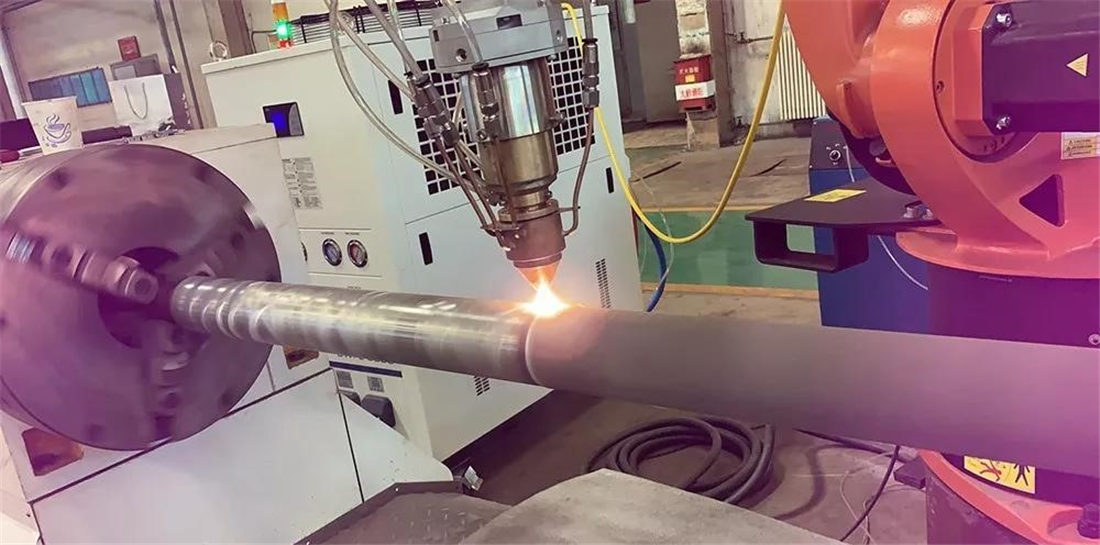

Laser cladding is a process method for additive modification of the metal surface. It is to place the alloy powder on the surface of the cladding substrate with different filling methods, use the laser as the heat source to quickly melt the alloy powder, and form a coating with excellent performance on the surface of the substrate, to modify or add materials to the surface of the workpiece.

The traditional process method is to electroplate a layer of hard chromium on the outer surface to meet its performance requirements, but the electroplating has serious pollution, and the chromium layer itself has defects such as large porosity, which is gradually replaced by the new process laser cladding. Compared with the electroplated layer, the cladding layer has greatly improved performance and service life.

WILA's standard process:

1. Incoming material inspection

Carry out hardness testing, coaxial testing, and flaw detection on incoming products to ensure that products that require laser cladding can meet quality requirements.

2. Incoming machining

For products with hardened layers and defects to be tested, they can not flow into the next process until they pass the test in the form of machining and turning, and the tolerances that need to be cladding are recorded.

3. Tooling

Install the qualified incoming materials on a special laser cladding machine tool, (make sure that the coaxial line is within 0.08mm) wipe clean the surface of the workpiece with industrial alcohol.

4. Cladding processing

According to (the size of the workpiece, the thickness of the cladding, the performance requirements of the coating after cladding), edit and call the mature process parameters and choose to add the corresponding powder to start the laser cladding.

5. Machining after cladding

According to the original workpiece drawing, the required size and surface finish machine can be added to meet the requirements.

6. Factory inspection

Carry out the hardness, size, and flaw detection of the processed workpieces, and deliver the goods if they are qualified.

OEM Services:

In addition to repairing hydraulic rods with various metal defects such as wear, corrosion, chrome marks, scratches, and strains on the surface, WILA Laser. We can also directly produce hydraulic rods with high hardness, high wear resistance, corrosion resistance, high-temperature resistance, and non-magnetic properties on your behalf.

Our professional technicians are waiting for your consultation at any time and will provide solutions quickly.

click here to leave a message