Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

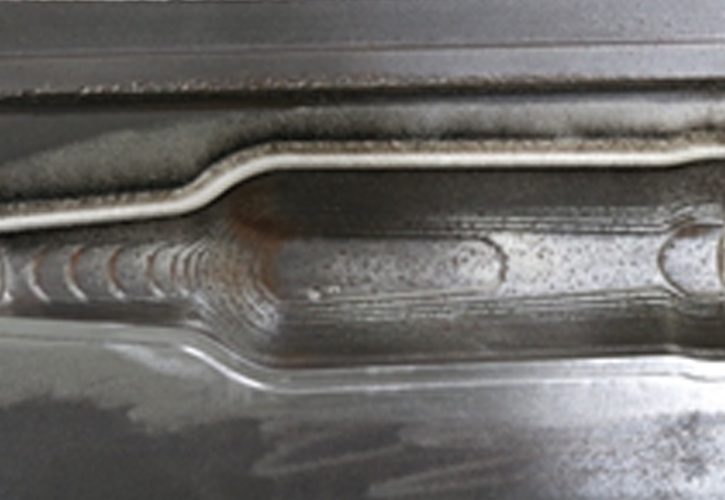

The joint surface of the glass mold is prone to wear, corrosion, thermal fatigue cracks, oxidation, etc. during use, which can lead to mold failure.

Using laser 3D printing technology to prepare advanced high-temperature wear-resistant and corrosion-resistant nickel-based alloy coating on its surface. The coating has excellent wear resistance, corrosion resistance, high-temperature oxidation resistance, and high-temperature thermal fatigue properties, which can greatly increase the service life of the mold.

Payment:

TTProduct origin:

ChinaShipping port:

ShanghaiLead Time:

20 days after receiving the depositRepair of glass mold joint surface

In the glass forming process, the mold is required to withstand high-temperature conditions for a long time. The glass entering temperature is between 900~1100℃, and the exit temperature is about 500~600℃. The temperature difference between glass entering and exiting the mold is 400~500℃. If the mold material cannot withstand the impact of the rapid cold and heat resistance, it will cause the mold to crack and affect the quality of the product. No matter which glass molding method is used, it is very poor in terms of the operating conditions of the mold. Because of the many complex physicals, chemical, and mechanical processes that occur in hot glass forming and final production of finished products, the requirements for mold materials are extremely demanding. Generally, glass molds should have the properties of heat resistance, wear resistance, chipping resistance, and heat shock resistance.

WILA Laser uses a laser beam to melt the coating material and thin-layer base material. After rapid solidification, it forms a cladding layer with extremely low dilution and roughly the same composition as the coating. It can form alloy ceramics with a hardness of 60HRC on the surface of the glass mold. Cladding layer, thereby improving the wear resistance, corrosion resistance, heat resistance, and oxidation resistance of the surface of the substrate material. It can also restore the worn glass mold to size, similar quality, and same performance repair. The glass mold processed by laser cladding repair technology has less heat input during cladding, has little effect on the overall structural size of the glass mold, and will not cause the risk of deformation of the glass mold, and the laser cladding layer is very flat, which can not only make The damaged part of the surface restores the external dimensions as required, and also improves the surface corrosion resistance and wear resistance, thereby prolonging the service life and saving the cost of purchasing new products.

click here to leave a message