Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

Payment:

TTProduct origin:

ChinaGoods stock:

5Shipping port:

ShanghaiLead Time:

20 days after receiving the deposit

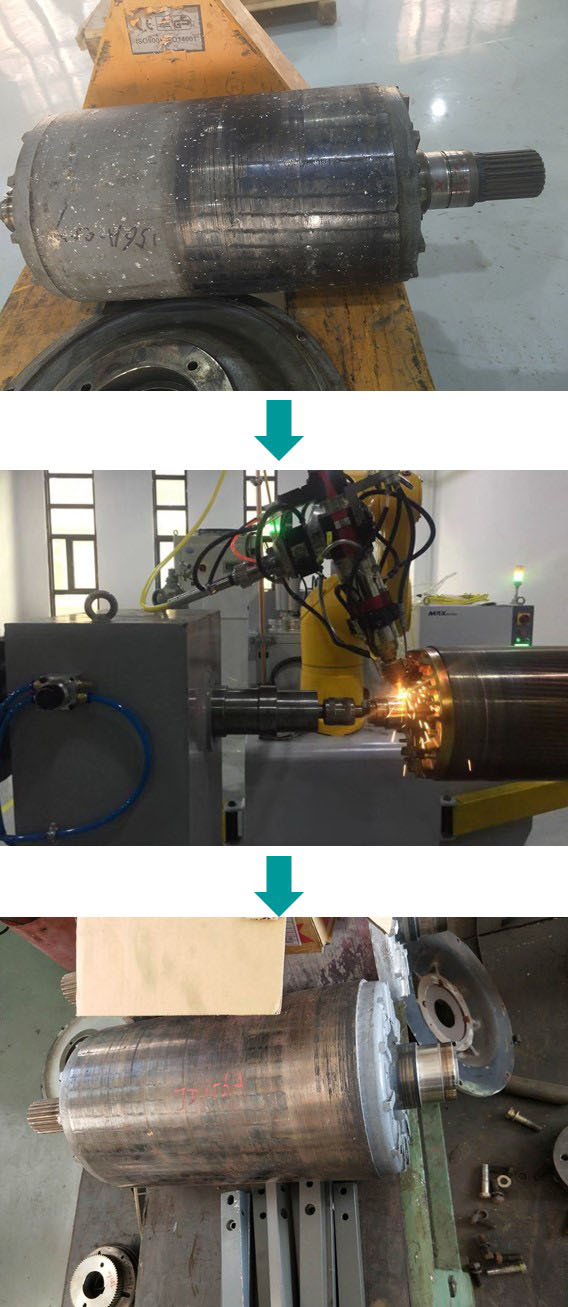

Motor rotor shaft repair

Product description:

Repair name: Motor rotor shaft (electric bus motor rotor shaft)

Repair material: 45 steel, 35CrNoMo

Basic situation: The long-term overload of the bus causes the motor to work overload, the electric bus suddenly brakes the motor to lock instantly during the operation, the shaft and the end cover form a non-mechanical rotation and the product is worn out, and the electroplating part of the end cover falls off. The traditional electroplating process can only last for 3-4 months.

Repair requirements:

1. The concentricity error of the end cover of the bearing chamber does not exceed 0.02mm in diameter

2.The cylindricity of the bearing chamber does not exceed 0.006mm.

3. Surface roughness Ra=1.6, end face chamfer C1.

4. After repairing, there should be no pores, slag inclusions and unfusion.

click here to leave a message