Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

Payment:

TTProduct origin:

ChinaGoods stock:

100Shipping port:

ShanghaiLead Time:

20 days after receiving the deposit

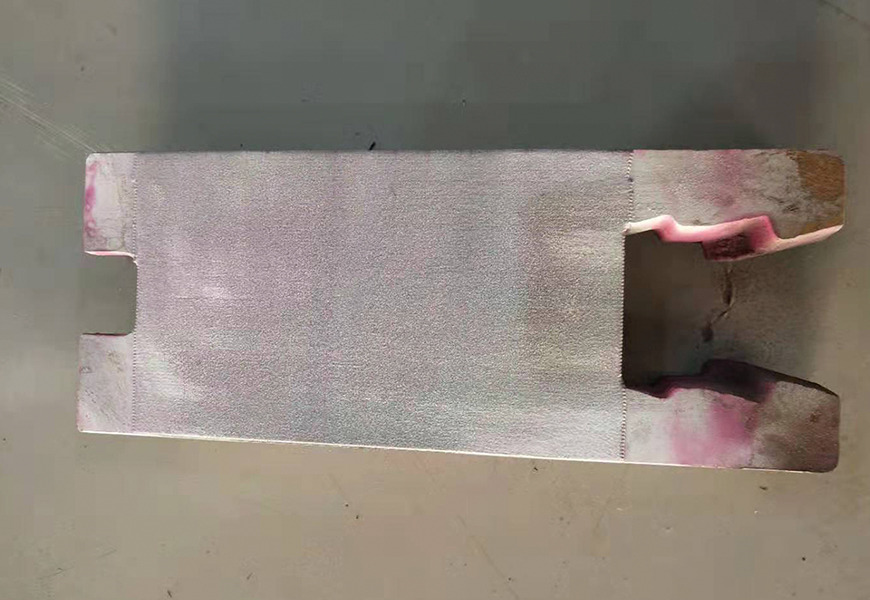

Railway track switch repair

Product Description:

Repair name: high-speed sliding bed platen

Material name: ZG230-450

Basic situation:

The high-speed turnout slide bed is frequently subjected to pressure and friction during long-term use. The traditional composite plating process is seriously polluted, and the bonding force between the coating and the base of the platen is poor, which easily causes the coating to peel off.

Repair requirements:

1. Corrosion resistance:

The protection level after 200 hours of neutral salt spray (NSS) test is not lower than the level 9 in GB/T 10125-2012.

2. Wear resistance:

The Rockwell hardness of the cladding should be HRC≥40, (hard chromium plating micro-Vickers hardness requirement≥HV800).

3. Strength of bonding layer:

According to the requirements of GB/T 8165-2008, the shear strength is ≥210MPa; the inner and outer bending tests should ensure that when the bending angle reaches 90°, the bonding layer and the coating have no visible cracks.

Before cladding

After cladding

click here to leave a message