Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

Payment:

TTProduct origin:

ChinaGoods stock:

100Shipping port:

ShanghaiLead Time:

20 days after receiving the deposit

High-pressure turbine blades repair

Product Description:

High-pressure turbine blades, as a key hot-end component, are a decisive factor in the minimum life cycle of modern high-performance engines. During use, the blade tip fretting and fatigue cracks lead to scrapping. The intake side of high-vortex blades often suffers from burning. The conventional arc welding method has a large heat-affected zone and uncontrollable deformation, which cannot be used for blade tip repair.

Product Show:

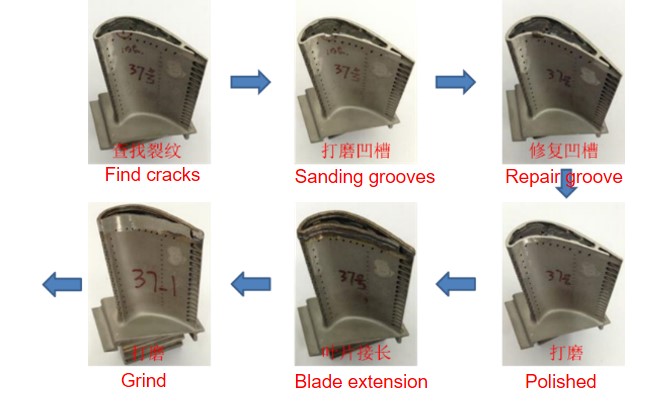

Case 1. High vortex blade repair

High-pressure turbine blades are prone to cracks due to the formation of low-melting eutectic phases during repair. The thickness of the blade is uneven, the heat accumulation state and temperature gradient of different parts are different, the process window is narrow, and precise energy density control is required to achieve a good molding effect.

A certain brand of high-pressure turbine blade can achieve the following technical effects after WILA repair:

• The thinnest part of the tip reaches 0.3mm;

• "Zero" deformation;

• Dense structure, no microcracks, pores and other defects;

• The depth of the heat-affected zone is not more than 200μm

• The performance of the additive material is better than that of the blade base, and the performance reaches or exceeds the original part;

Case 2. Burning loss of cast alloy high vortex blades

Nickel-based superalloys are widely used in the manufacture of turbine blades and guide vanes for aero-engines because of their good high-temperature strength and corrosion resistance and can be used for a long time in an engine working environment below 1000 ℃. During the long-term use of aero-engines, the turbine blades are subject to wear, impact, high-temperature gas, and thermal fatigue, which may cause cracks, wear, and corrosion to cause a large number of blades to be scrapped.

click here to leave a message