Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

Ultra-high-speed laser cladding technology is mainly used to improve the wear resistance, corrosion resistance, high-temperature resistance, and oxidation resistance of the surface of the parts, so as to achieve the goal of surface modification or repair, and meet the requirements for the specific performance of the material surface.

Payment:

TTProduct origin:

ChinaShipping port:

ShanghaiLead Time:

20 days after receiving the deposit

High speed laser cladding system

Product description:

In the conventional laser cladding process, laser energy is mainly used to melt the base material to form a molten pool. The powder is poured into the molten pool and melted, and then solidified to form a protective coating.

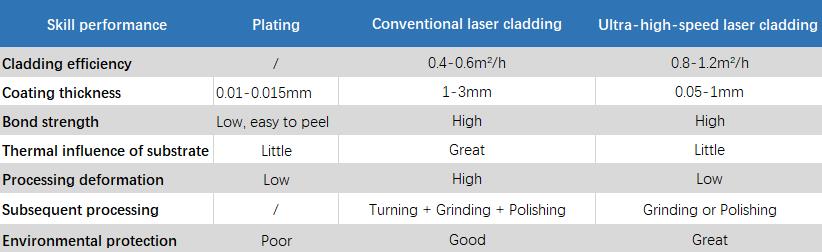

The ultra-high-speed laser cladding technology essentially changes the melting position of the powder, so that the powder meets the laser and melts above the workpiece, and then uniformly coats the surface of the workpiece. Its cladding rate can be as high as 20-200m/min. Due to the low heat input, this technology can be used for surface cladding of heat-sensitive materials, thin-walled and small-sized components, and it can be used for brand-new material combinations, such as aluminum-based materials, Preparation of coatings on titanium-based materials or cast iron materials. Since the surface quality of the coating is significantly higher than that of ordinary laser cladding, it can be applied only by simple grinding or polishing. Therefore, the waste of materials and subsequent processing are greatly reduced. Ultra-high-speed laser melting is in terms of cost, efficiency, and thermal impact on parts. Covering has an irreplaceable application advantage.

Technical advantages

Efficient and low cost

• Cladding line speed 20-200m/min

• Cladding efficiency 0.8-1.2m²/hr (depending on coating thickness)

• The powder utilization rate can reach more than 95%

• There is no need for subsequent turning processing, and it can be directly ground or polished

High quality and adaptability

• The hardness of the super hard wear-resistant coating can reach above HRC65, which is suitable for various surface friction and impact wear

• Applicable coating thickness 0.05-1mm

• High surface quality, the surface roughness can reach Ra25μm after cladding

Low heat input

• Low laser power requirements

• Little impact on the substrate, small deformation of parts

• The best solution for surface cladding of parts with large aspect ratio, thin-walled and heat-sensitive materials

Industry Application:

1. Coal machinery:

Used in the preparation of corrosion-resistant coatings on the surface of shaft parts such as piston rods, movable columns, and middle cylinders of hydraulic supports; due to low heat input and small deformation, it has unique advantages in surface cladding of parts with large aspect ratios .

2. Hoisting machinery:

It can be used for the preparation of wear-resistant and corrosion-resistant coatings on the surface of shaft parts of different sizes such as hydraulic cylinders, piston rods, and columns;

3. Offshore engineering machinery:

It can be used for efficient preparation of wear-resistant and corrosion-resistant coatings on the surface of shaft parts of different sizes such as offshore platform columns, steam turbine rotors, drive shafts, etc.

4. Iron and steel metallurgy:

It can be used for the efficient preparation of wear-resistant and high-temperature-resistant coatings on the surface of different sizes of shaft parts such as rolls, process rolls, and transfer rolls.

5. Mould industry:

It can be used for efficient preparation of wear-resistant and high-temperature resistant coatings on the surface of axisymmetric parts of different sizes;

6. Petroleum industry:

Used for rapid preparation of wear-resistant coatings on axisymmetric parts such as impellers, large rotor journals, sleeve shafts, and wheel discs

click here to leave a message