Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

The camshaft is an important transmission component of the fuel injection pump, which determines the oil supply interval and pump oil pressure of the whole machine and the overall service life of the fuel injection pump. After the camshaft is worn, it will cause abnormal fuel supply intervals, resulting in unstable operation of the diesel engine and insufficient overall engine power.

Payment:

TTProduct origin:

ChinaMin order:

10Shipping port:

Shanghai portLead Time:

20days after receiving depositCamshaft laser cladding

Product Description:

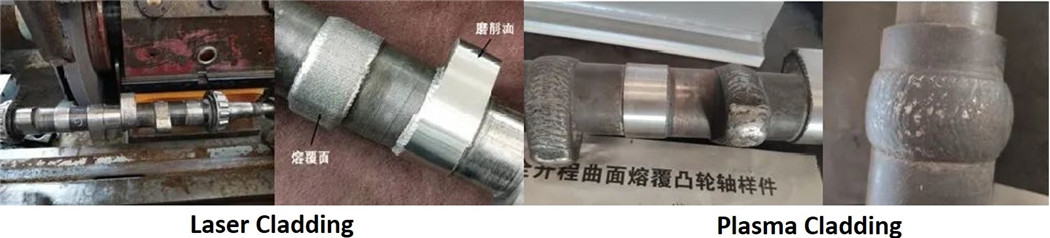

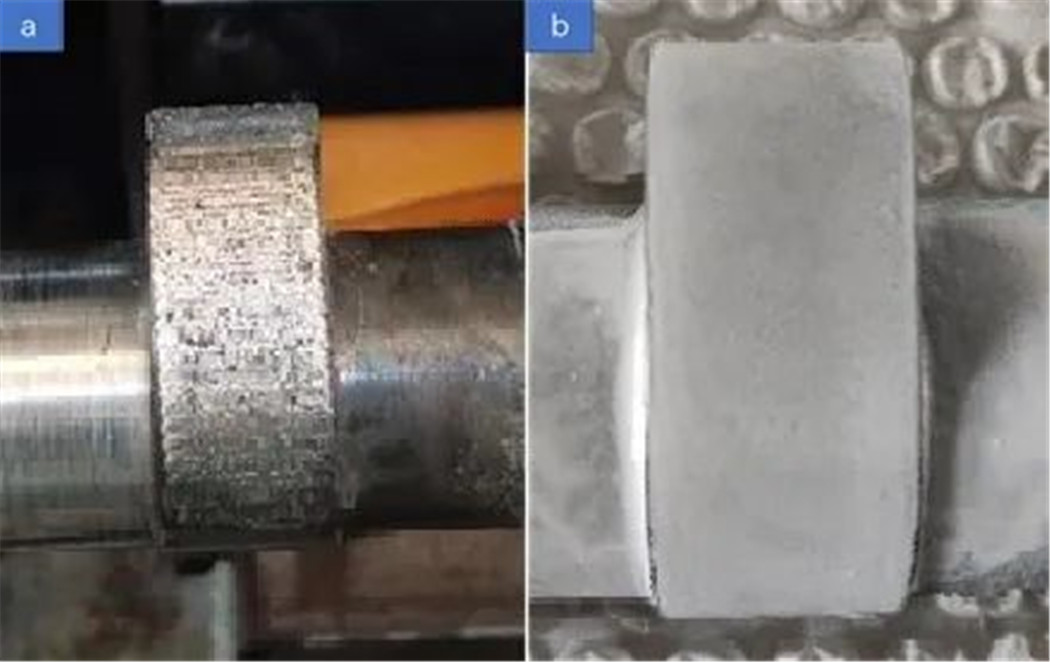

The camshaft is an important part of the diesel engine. During the working process, the cam lift surface bears the alternating stress load for a long time, resulting in different degrees of wear failure. The laser cladding technology is used to repair the serious damage to the lift surface of the fuel injection pump camshaft, which overcomes the problem that the conventional repair methods can easily cause the entire shaft to deform. A 6-kilowatt fiber laser is used to obtain a high-hardness laser cladding layer on the cam wear surface. The hardness, microstructure, and performance of the cladding layer are measured by surface PT inspection, Vickers hardness tester, metallographic microscope, and friction and wear. Characterization. The results show that the coating thickness is about 1 mm; the microhardness is 650 HV, the coating structure is dense, the grains are fine, and it is metallurgically combined with the substrate; the wear resistance of the cladding layer is better than the cam body, and the camshaft repair quality is good, satisfy Requirements.

The cam dimensional accuracy and performance requirements of the camshaft are very high. The traditional welding repair method is likely to cause the overall deformation of the work piece due to the large heat input. Other surface treatment methods such as spraying or brush plating are often difficult to meet the performance requirements due to insufficient bonding strength with the substrate. Laser cladding is an ideal technical means for the manufacturing of mechanical equipment parts. The technology has a small heat input, is not easy to cause deformation of the work piece, and can prepare high-hardness and wear-resistant coatings. The coating and the substrate are metallurgically bonded, and the coating is cladding High strength, not easy to fall off,

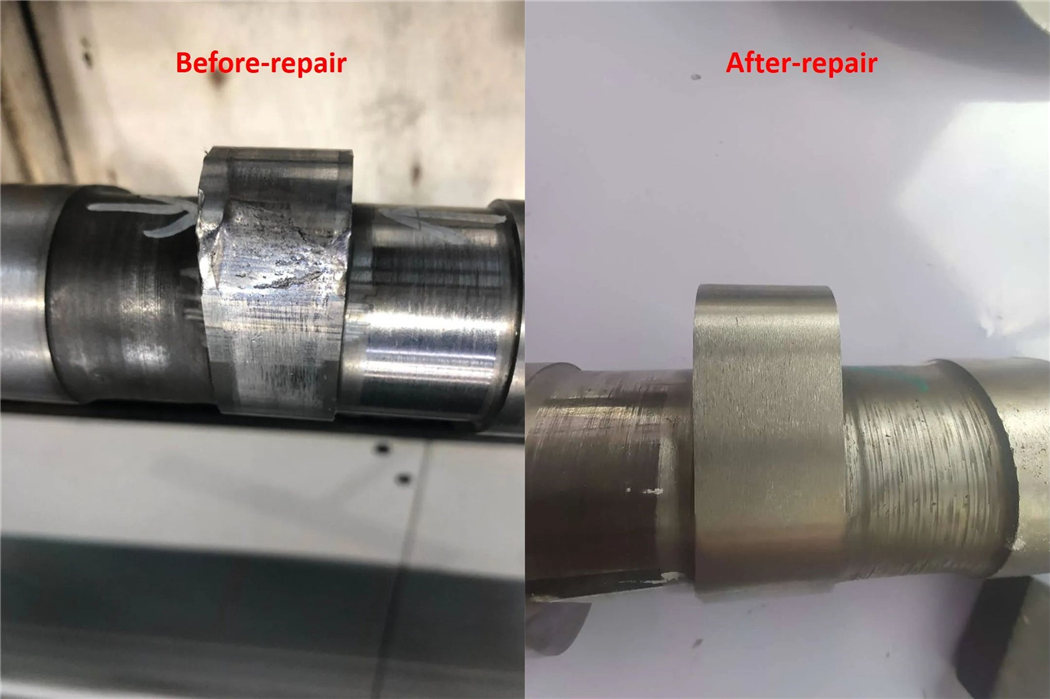

Repairing Comparing:

During the rotation of the camshaft, the surface of the cam is affected by the cyclical pressure stress, which will cause the surface of the cam lift to be constantly subjected to periodic friction. The excessive wear of the cam lobe and nearby areas is the main reason for the failure of the cam.

click here to leave a message