Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

Laser cladding technology can directly use direct metal deposition to realize the repair and direct molding of single crystal parts. And to ensure theproperties of the single crystal, to avoid the formation of miscellaneous crystals.

Payment:

TTProduct origin:

ChinaGoods stock:

100Shipping port:

ShanghaiLead Time:

20 days after receiving the deposit

Aeroengine single crystal blade repair

Product Description:

With the further improvement of engine efficiency, the working temperature of engine hot end components further rises, and the performance requirements of the alloy are getting higher and higher. Nickel-based superalloys are gradually developing to single crystals with better high-temperature performance, such as Rene N5, CMSX-4, DD432, etc., have now developed to the fifth generation of nickel-based single crystal superalloys, and the operating temperature of each generation of superalloys is approximately 25°C higher than the previous generation.

The WILA technical team has made the following breakthroughs after exploring and researching the laser cladding process and metallographic analysis:

1. The maximum single-pass cladding width is 2mm, and the continuous stacking can reach a height of 10mm.

2. The thickness of the single-layer can be adjusted within 0.5mm.

3. The amount of impurity crystals on both sides is less than 10%.

4. The high-temperature tensile properties of the bonding interface at 800°C reach >90% of the base material, and the strength of the cladding layer should not be less than 90% of the base material.

5. The length of the single-crystal blade tip adopts the coaxial precision nozzle and cladding process developed by Huirui, and the amount of impurity crystal is 5-10%. The process is stable and can be continuously extended to 10mm.

Product Show:

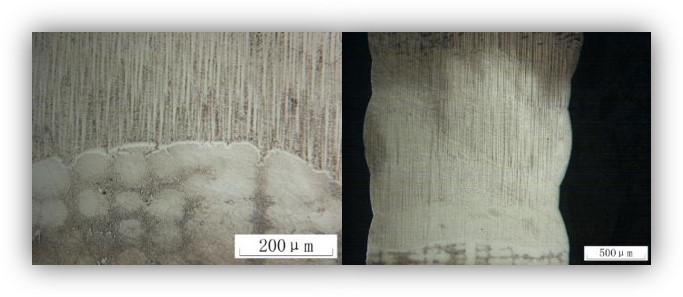

Nickel-based superalloy epitaxial extension bonding interface

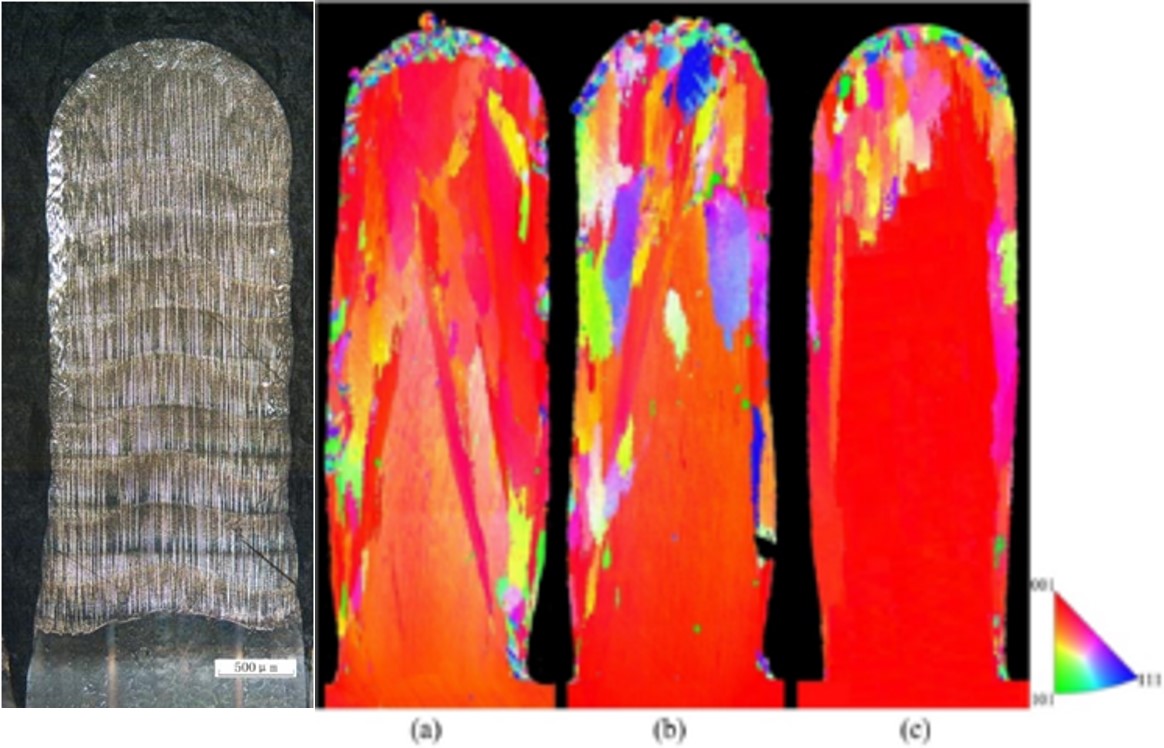

EBSD pictures of cross-sections of continuous 10-layer growth single crystal material cladding obtained under 3 sets of different processes. The color represents the crystal growth direction, and the red color is the [001] direction that is consistent with the substrate crystal direction. Through process optimization, the continuous cross-layer oriented crystalline microstructure as shown in the rightmost cross-section can be obtained. The feasibility of the repair molding process of single-crystal alloy materials was verified.

click here to leave a message