Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

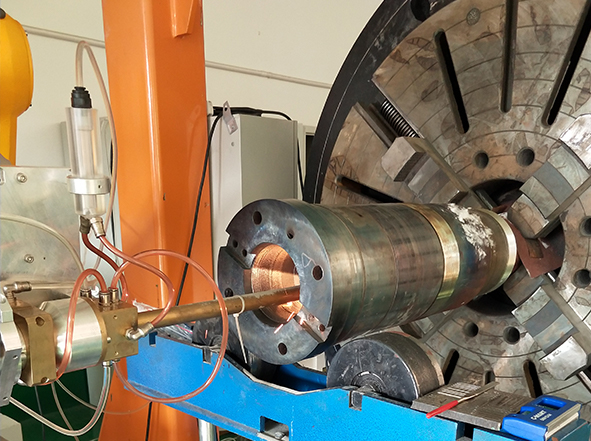

Remanufacturing and repairing damaged parts is an important way to recover huge economic and time losses, improve resource utilization, and realize the sustainable development of the national economy. Select alloy powders with excellent performance for laser cladding repair, analyze the macro/microstructure characteristics, hardness and wear resistance of the laser cladding layer, and then grind the cladding layer to realize the remanufacturing of the lathe spindle

Payment:

TTShipping port:

FOB:Shanghai PortLead Time:

20 days after received depositCNC milling machine spindle repair:

With more than ten years of experience and expertise to diagnose where the problem is, and obtain high-speed spindle repair services, high-speed spindle reconstruction and spindle replacement operations are completed in time, excellent spindle service can provide you with high-quality repair services you can trust

We serve many different types of spindles. Our in-house and on-site spindle repair services and spindle reconstruction services include vibration analysis, spindle and bearing repairs, spindle taper grinding, complete statistical reports and industry-leading engineering recommendations.

Service details

Repair device name: 25m CNC milling machine

Repair material: alloy steel (60#)

The basic situation of repairing: Because the equipment has long-term compliance with the inner wall of the working spindle, the wear unilateral 0.5mm, the traditional technology can not be repaired after wear.

Repair requirements:

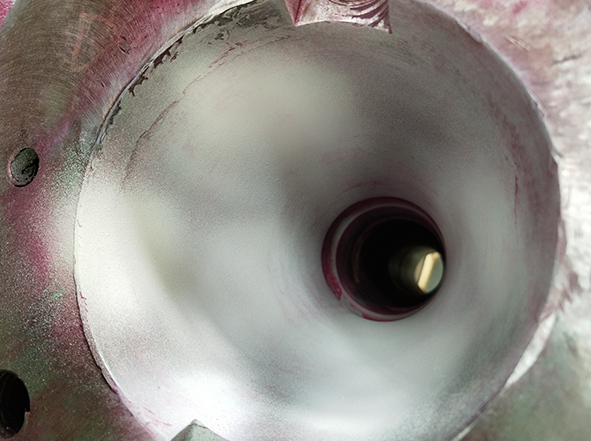

1. After grinding and repairing, the radial circle runout tolerance of the spindle taper hole is: 0.01mm at the proximal shaft end, 0.03mm at the 300mm far shaft end, and the spindle axial stringing tolerance 0.01mm;

2. After grinding and repairing, the surface roughness of the spindle taper hole should not be less than Ra0.8, and the contact area should not be less than 75% using standard inspection rods, and the big end contact should be close;

3. The width tolerance of the keyway of the spindle end face is 270﹢0.025mm, and the parallelism tolerance is 0.01mm.

Inner hole repairing

Flaw detection after cladding

Customer acceptance

click here to leave a message