Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

EHLA WILA Laser Clad Equipments Introduction

May 24 , 2021WILA Product Introduction:

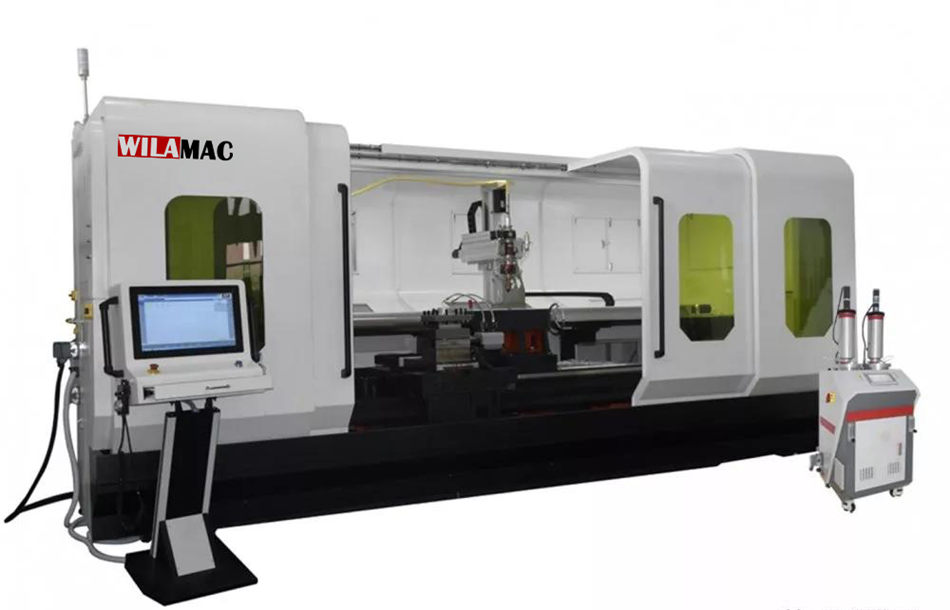

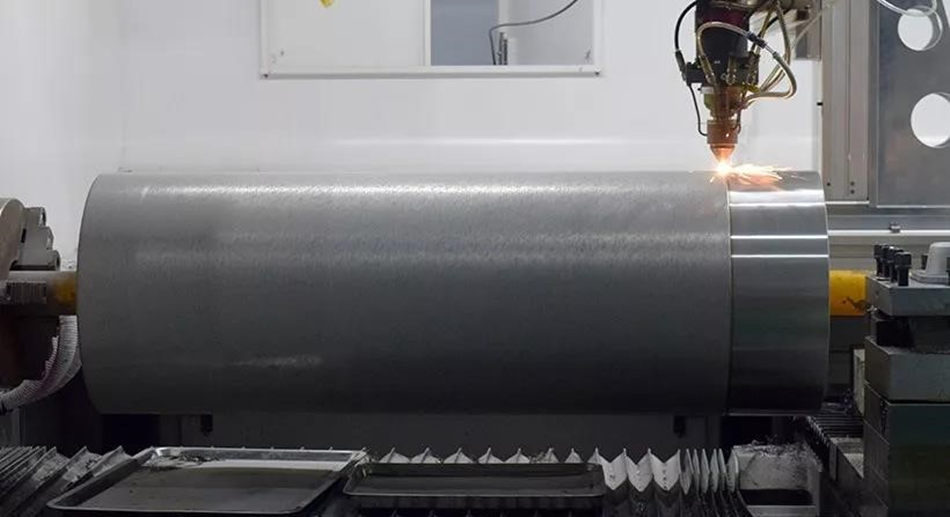

The second-generation ultra-high-speed laser cladding equipment independently developed by WILA is composite equipment that integrates turning, cladding, and mirror processing. After the shaft parts are clamped and positioned once, the increase/decrease process and mirror surface processing can be completed in sequence, which avoids the problem of round runout errors caused by multiple clamping and greatly improves the quality and production efficiency of the coating. The equipment is more integrated, the appearance is more beautiful, and the operability and reliability are higher. At the same time, it effectively reduces metal powder spillage, which is healthy and environmentally friendly.

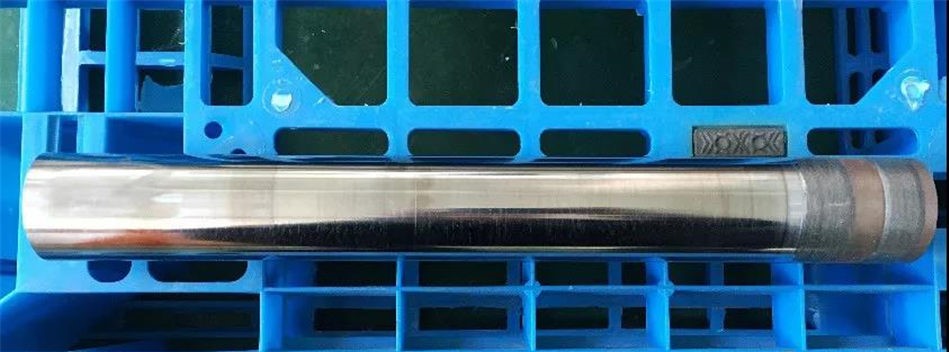

The appearance of cladding layer

The single-layer cladding thickness of martensitic stainless steel material is about 0.5mm, the surface efficiency is 0.6m2/h, the surface of the cladding layer is metallic luster, the cladding layer is continuous and dense, and there are no defects such as voids and cracks.

Roughness:

Use a roughness measuring instrument to measure the surface roughness of the cladding layer of the second-generation ultra-high-speed cladding equipment, and obtain the roughness data in the table below. The measurement points are located at equal distances from the beginning of the cladding to the end of the cladding. , The average roughness is about 6um.

| Test Point | 1 | 2 | 3 | 4 | 5 | 6 |

| Ra(um) | 5.70 | 5.81 | 6.08 | 5.66 | 6.60 | 6.19 |

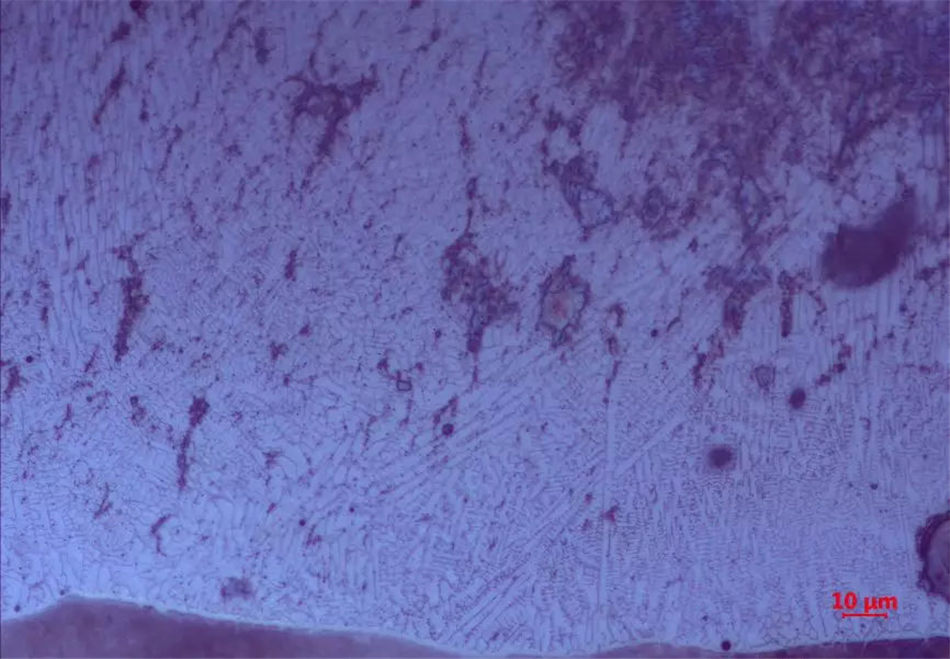

Metallographic diagram:

The cladding layer is well bonded to the base material, there is no non-fusion phenomenon, the dilution rate is less than 1%, and the microstructure of the coating is a mixed structure of δ-Fe + martensite.

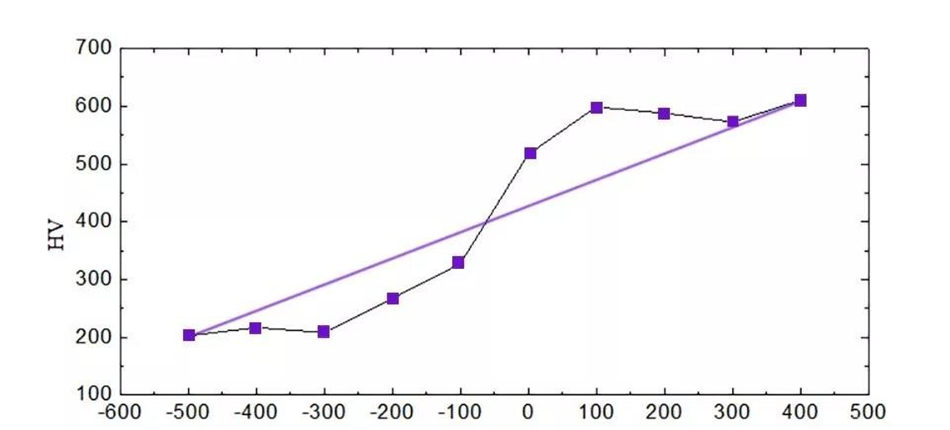

Hardness

Measure the microhardness of the cross-section of the cladding layer, the loading force is 200gf, and the holding time is 10s; the bonding position of the cladding layer and the substrate is taken as the 0 point position, and the hardness value is measured every 100um in the negative direction, that is, the substrate direction. In the positive direction, the hardness value is measured every 100um in the direction of the cladding layer, and the data in Table 2 can be obtained; the hardness change trend can be seen from Figure 3, the highest value of the cladding layer hardness reaches 610HV.

| Deposition | -500 | -400 | -300 | -200 | -100 | 0 | 100 | 200 | 300 |

| Hardness | 202.9 | 216.4 | 208.6 | 267.2 | 327.4 | 517 | 599 | 588 | 573 |

Mirror processing

Using ultrasonic polishing to mirror surface after finishing turning the surface of the cladding layer, the surface roughness after processing is about Ra0.2;

Cladding scene and details

click here to leave a message