Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

Laser cladding of free-form surfaces | Lasercladdingtech.com

May 08 , 2021Abstract:

Laser cladding technology uses high-energy laser beams to melt metal materials, and metallurgically combines with the base material to form a cladding layer with corrosion resistance, wear resistance, high hardness and excellent mechanical properties, which can repair damaged surfaces of parts and prolong the service life of parts. Used for surface strengthening of parts.

For uniform cross-section parts, the cladding scanning path is generally generated by the parallel slicing method; however, for the laser cladding of free-form surfaces in space, due to the non-developable characteristics and gradient changes of the three-dimensional surface, the parallel slicing method will cause the gap between the cladding channels to be different. Wait. The uneven density of the melt channel will cause the cladding layer to bulge or sag, and the thickness is uneven, which seriously affects the surface quality of the cladding.

Analysis:

In response to the above problems, WILA technicians and the research team of Soochow University proposed an equal lap rate cladding path planning algorithm based on the point cloud. A smooth and uniform fusion channel was obtained on the free-form surface, and the cladding nozzle was ensured during the processing. It is always perpendicular to the machined surface, achieving uniform laser cladding of free-form surfaces.

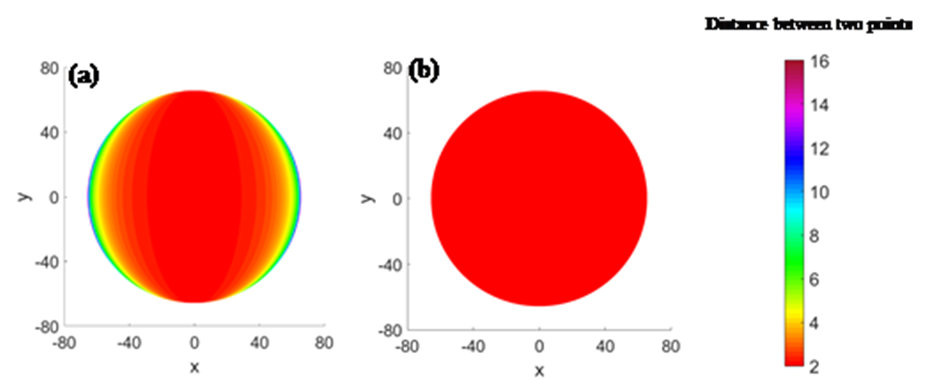

In order to verify the rationality of the algorithm, WILA strengthened the hemispherical head by laser cladding. Taking the center of the hemisphere as the origin, pick two points P1 and P2 on the adjacent melt channel. Figure 1(a) shows the distance between the two points P1 and P2 after using the equidistant slicing method along the x direction; Figure 1(b) shows the distance between the two points after using the algorithm in this paper. It can be seen from the figure that when the equidistant slicing method is used for cladding, the distance between adjacent melting channels is quite different; and after using the algorithm in this paper, the distance between adjacent melting channels is equal.

During the cladding process, the normal vector of each processing point is calculated, and the robot posture is changed to keep the cladding nozzle always perpendicular to the processing surface. The cladding process and the surface of the cladding layer are shown in Figure 2.

Figure 2 Laser cladding process and physical diagram of the cladding layer

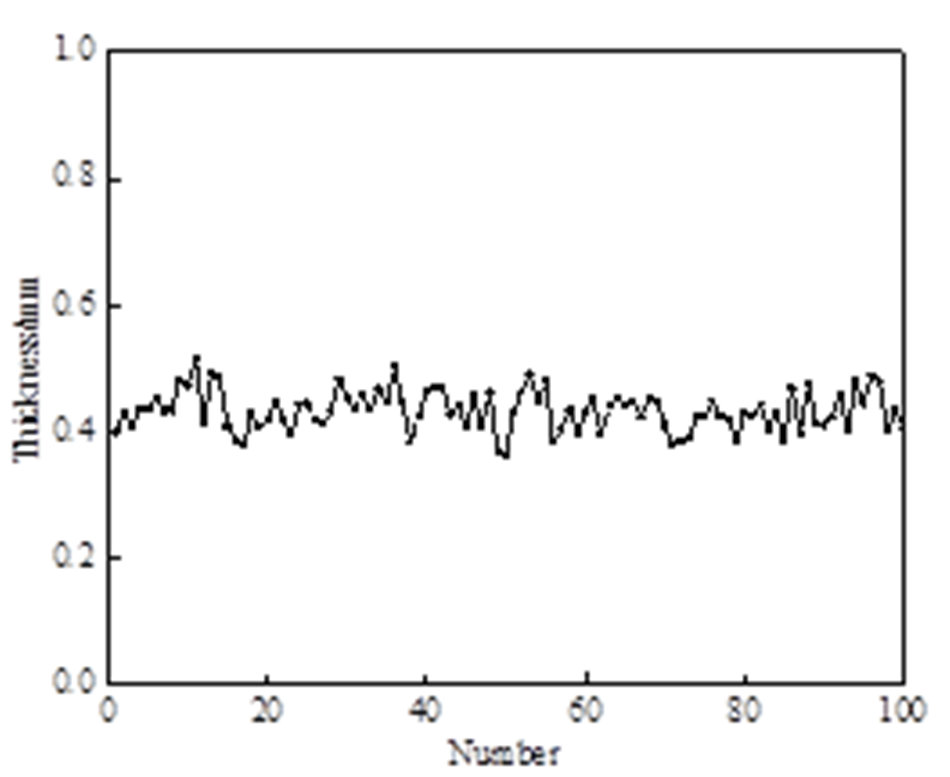

Select 100 different positions to measure the thickness of the cladding layer, as shown in Figure 3. The average cladding thickness is 0.434 mm, and the standard deviation is 0.032 mm. The waviness of the cladding layer is small, the overall cladding thickness of the cladding layer is uniform, there are no obvious defects such as bumps or depressions between tracks, and the surface appearance is good.

Figure 3 Thickness of cladding layer

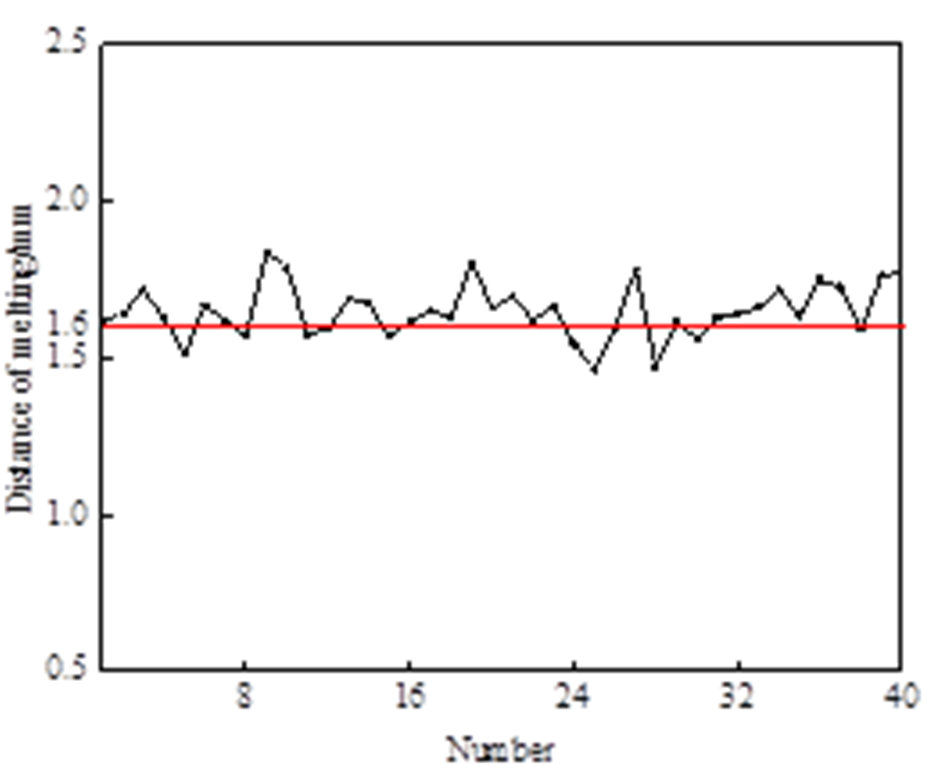

The distance between the cladding channels is shown in Figure 4. The distance between the channels fluctuates between (1.6 ± 0.2) mm, and the range is small, indicating that this method can ensure the equal distance between the channels, which means that the channel distance is equal. Lapping rate.

Figure 4 Distance between adjacent melt channels

Conclusion:

Experimental data shows that the equidistant trajectory planning method combined with the adjustment of the cladding nozzle posture can achieve uniform laser cladding of free-form surfaces, and can be used to complete laser cladding strengthening of various spatial curved parts.

click here to leave a message